Exactly How to Make Certain Longevity and Reliability with a High-Quality Membrane Switch

Exactly How to Make Certain Longevity and Reliability with a High-Quality Membrane Switch

Blog Article

How Membrane Switches Add To the Sturdiness of Electronic Control Panels

Membrane layer buttons play an important function in boosting the longevity of electronic control board, mostly through their multi-layered building and construction which provides effective protection versus ecological aspects such as moisture and dust. This design not just reduces the threat of circuit damage and deterioration but additionally advertises convenience of upkeep due to its smooth surface. Moreover, the lack of moving parts significantly minimizes the possibility of mechanical failures, making membrane switches over perfect for requiring applications. The effects of these features expand past mere defense, elevating questions regarding their wider influence on capability and customer experience.

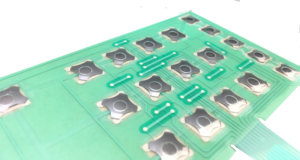

Interpretation of Membrane Switches

Membrane switches are developed to be slim and light-weight, making them ideal for applications where space is limited. They can be manufactured in numerous shapes, dimensions, and shades, supplying adaptability in layout that satisfies visual and practical requirements. In addition, membrane switches can include various technologies, such as responsive feedback and LED indications, enhancing individual experience.

Due to their construction, membrane buttons are typically resistant to dirt, dampness, and general wear, adding to their toughness sought after atmospheres. Their smooth layout not only promotes simple cleansing but likewise minimizes the risk of mechanical failing, making them a recommended choice for makers looking for trusted user interfaces in their electronic control board.

Protection Versus Ecological Factors

The design of membrane switches over inherently supplies a degree of defense versus different environmental elements, which is essential for keeping performance in difficult conditions - Membrane Switch. These switches are usually built with layers of flexible materials that shield interior parts from wetness, dirt, and impurities. By encapsulating the wiring, membrane switches over lessen the risk of brief circuits and rust, which can dramatically impair performance

In addition, the use of robust adhesives and sealers during manufacturing improves their resistance to environmental difficulties. Membrane switches can endure direct exposure to chemicals and solvents, making them suitable for sectors such as food handling and healthcare, where hygiene and tidiness are vital. Their seamless surface design also prevents the accumulation of dirt and bacteria, helping with easier cleansing and upkeep.

Temperature fluctuations are another ecological problem, and membrane switches are engineered to function efficiently across a wide variety of temperatures (Membrane Switch). This adaptability ensures that control board remain operational in various settings, from industrial environments to consumer electronics

Effect On Individual Interaction

Customer interaction with digital control board is substantially influenced by the layout and functionality of membrane layer buttons. These switches provide a tactile user interface that improves the general user experience, enabling for user-friendly navigating and control. Their receptive nature makes sure that customers receive immediate comments upon activation, which is essential for tasks requiring accuracy and efficiency.

In addition, the smooth surface area of membrane layer changes promotes simple cleansing and upkeep, promoting individual self-confidence in the integrity of the interface. This tidiness is particularly vital in atmospheres where hygiene is critical, such as medical or food processing settings. Additionally, the compact and light-weight design of membrane layer switches adds to the aesthetic appeal of control panels, motivating individual involvement via a contemporary and streamlined appearance.

Furthermore, the assimilation of visual elements, such as published symbols and backlighting, helps users rapidly determine features, decreasing the finding out curve connected with brand-new devices. Because of this, individuals can operate tools better, resulting in boosted productivity and satisfaction. In summary, membrane layer buttons play a critical role in improving user interaction by combining capability, visual appeals, and ease of usage, eventually causing improved operational performance.

Style Versatility and Modification

Design adaptability and modification are vital elements of membrane Continue layer buttons, enabling makers to tailor electronic control board to particular applications and customer requirements. This adaptability permits the integration of different style elements, such as colors, graphics, and structures, which can boost Read More Here the visual charm and customer involvement of the control board.

Membrane switches can be tailored in size and shape, accommodating a broad range of devices and applications, from industrial equipment to customer electronic devices. This flexibility guarantees that makers can develop intuitive interfaces that align with customer assumptions and functional needs. Furthermore, the capability to integrate unique attributes such as backlighting or responsive comments further improves use, enabling an extra interactive experience.

Additionally, the production process for membrane layer switches over sustains the rapid prototyping of styles, allowing makers to iterate and refine their concepts promptly. This capability not just speeds up the advancement timeline but also makes sure that the end product satisfies details useful and visual requirements.

Cost-Effectiveness and Durability

Cost-effectiveness and durability are significant advantages of membrane buttons, making them an eye-catching alternative for producers and end-users alike. These switches are commonly less pricey to produce than standard mechanical switches, primarily due to their streamlined production procedures and the lowered variety of parts required. This expense advantage expands not just to initial production but also to lasting operational costs, as membrane layer switches typically need less maintenance and have a reduced failure rate.

Moreover, the long life of membrane layer changes adds to their general worth. Constructed from durable products, they are immune to environmental elements such as wetness, right here dirt, and chemicals, which can result in premature wear in various other button kinds. The lack of moving components decreases mechanical failing, permitting membrane switches to maintain performance over extended durations.

This toughness is especially helpful in applications calling for consistent efficiency under demanding conditions, such as clinical tools and commercial equipment. Ultimately, the combination of cost-effectiveness and long life makes membrane layer changes a financially sensible option for suppliers, supplying trusted services that endure the test of time while enhancing financial factors to consider.

Verdict

In conclusion, membrane switches significantly improve the toughness of electronic control panels via their durable building and safety features - Membrane Switch. In general, membrane changes stand for a reliable and economical choice for boosting the durability and capability of digital control systems.

Report this page